Cane Carrier Slats by Mahalaxmi Industries : Durable Solutions for Efficient Sugarcane Handling

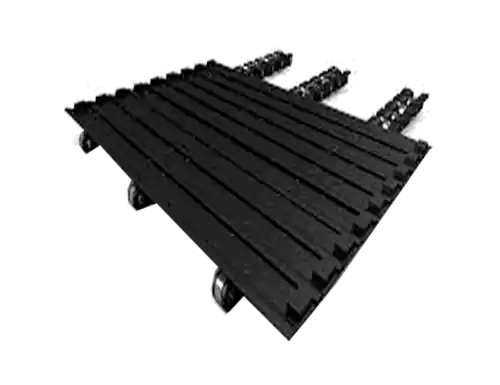

Cane Carrier Slat

Our Cane Carrier Slats are designed to efficiently transport sugarcane from the loading area to the crushing section of the mill. These slats are engineered for high strength and durability, ensuring long-lasting performance even in harsh operating conditions. The robust construction of our cane carrier slats minimizes wear and tear, providing excellent resistance to heavy loads and continuous usage. By using our cane carrier slats, sugar mills can enhance the efficiency of their sugarcane handling operations, reducing downtime and improving productivity.

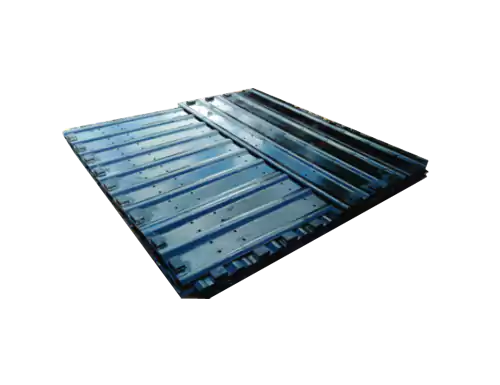

RBC Slat ( Return Bagasse Carrier Slat )

The RBC Slat is specifically designed for the Return Bagasse Carrier, a crucial component in the sugar extraction process. These slats facilitate the return of bagasse, a byproduct of sugarcane crushing, to the boilers for fuel. RBC slats are built to handle heavy loads and high temperatures, making them ideal for continuous operation in demanding environments. Their durable construction ensures that the return of bagasse is smooth and uninterrupted, contributing to efficient energy utilization within the plant.

MBC Slat ( Main Bagasse Carrier Slat )

Our MBC Slats are used in the Main Bagasse Carrier, which transports bagasse away from the crushing mill after the juice has been extracted. MBC slats are engineered to withstand the abrasive nature of bagasse and the high-pressure conditions of sugar mills. They ensure the smooth transportation of bagasse, preventing blockages and delays in the process. These slats play a vital role in keeping the sugar mill operations running efficiently, reducing maintenance requirements and improving overall output.

High Durability

Manufactured using premium materials, our cane carrier slats are built to last in harsh industrial environments. They resist wear, corrosion, and heavy loads, ensuring minimal downtime and longer service life.

Improved Efficiency

Our cane carrier slats help streamline the transportation of sugarcane and bagasse, reducing bottlenecks and improving the overall efficiency of sugar mill operations. Their robust design ensures smooth operation, even in high-demand situations.

Low Maintenance

Designed for continuous use, our slats require minimal maintenance, which helps reduce operational costs and ensures consistent performance throughout the sugarcane processing season.

Sugarcane Handling

Used to transport sugarcane from the loading area to the crushing mill, enhancing efficiency in the initial stage of sugar production.

Bagasse Handling

RBC and MBC slats are essential for transporting bagasse within the sugar mill, whether it’s returning it to the boiler for fuel or removing it from the production area.

Power Generation in Sugar Mills

RBC slats help facilitate the return of bagasse for use as fuel, supporting energy generation in cogeneration power plants.