Gears & Gear Spares by Mahalaxmi Industries : Precision-Engineered Power Transmission Solutions

At Mahalaxmi Industries, an ISO 9001:2015 Certified Company, we are proud to offer a comprehensive range of high-performance Gears & Gear Spares designed to meet the diverse needs of industrial power transmission. Our gears are manufactured using cutting-edge technology and precision engineering to ensure superior performance, durability, and reliability across various industrial applications. Whether you need gears for heavy machinery, automotive systems, or specialized equipment, we provide solutions that enhance efficiency and reduce maintenance costs.

Hypoid Gears

Hypoid Gears are used in applications that require smooth, quiet, and efficient transmission of power at non-parallel shaft angles. They offer high torque transfer and are ideal for use in automotive differentials, heavy-duty trucks, and industrial machinery.

Spur Gears

Spur Gears are the most common type of gear used for transferring motion and power between parallel shafts. They are highly efficient, easy to manufacture, and provide precise control, making them ideal for applications in industries like automotive, machinery, and robotics.

Worm Gears

Worm Gears are used for achieving high torque reduction in a compact space. They provide a smooth, quiet transmission with self-locking capabilities, making them suitable for conveyor systems, lifts, and heavy-duty machinery where precise movement is essential.

Screw Gears

Screw Gears are used for applications requiring the transmission of motion between non-parallel, non-intersecting shafts. They offer smooth and quiet operation, ideal for applications in machine tools and packaging equipment.

Internal Gears

Internal Gears are used where space constraints demand compact power transmission. These gears are commonly found in planetary gear systems and are used in applications like industrial machinery, automotive systems, and robotics.

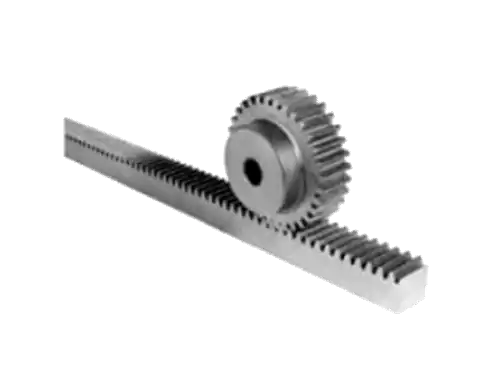

Rack Gears convert rotational motion into linear motion. They are essential in applications such as CNC machines, actuators, and material handling equipment, where precision linear movement is critical.

Herringbone Gears and Double Helical Gears are used for applications requiring high power transmission with minimal noise and vibration. Their unique tooth design allows for smooth, continuous operation, making them ideal for heavy-duty machinery like compressors, turbines, and large gearboxes.

Durability and High Performance

All of our gears are manufactured using premium materials, ensuring that they can withstand high loads, extreme temperatures, and harsh operating conditions. This durability guarantees long-term, reliable performance across various applications.

Precision Engineering

Our gears are precisely engineered for smooth, efficient power transmission. They reduce friction and wear, increasing the lifespan of machinery and minimizing maintenance requirements

Customizable Solutions

We offer a wide range of gears and spares, including custom configurations, to meet the specific needs of different industries. Whether it's for heavy-duty industrial machinery or precision equipment, we provide solutions tailored to your requirements.

Automotive Industry

Hypoid gears, spur gears, and worm gears are commonly used in transmissions, differentials, and powertrains

Machinery and Equipment

Spur, internal, and rack gears are widely used in industrial machines, packaging equipment, and CNC machines for precise power transmission and motion control.

Power Plants and Heavy-Duty Machinery

Herringbone and double helical gears are essential in turbines, compressors, and large gearboxes for efficient and quiet operation under high loads.

Robotics and Automation

Rack gears, spur gears, and internal gears are used in robotic arms, actuators, and automation systems to ensure precise movement and positioning.

Conveyor Systems and Elevators

Worm gears provide high torque reduction and smooth operation in conveyor belts and lift systems.